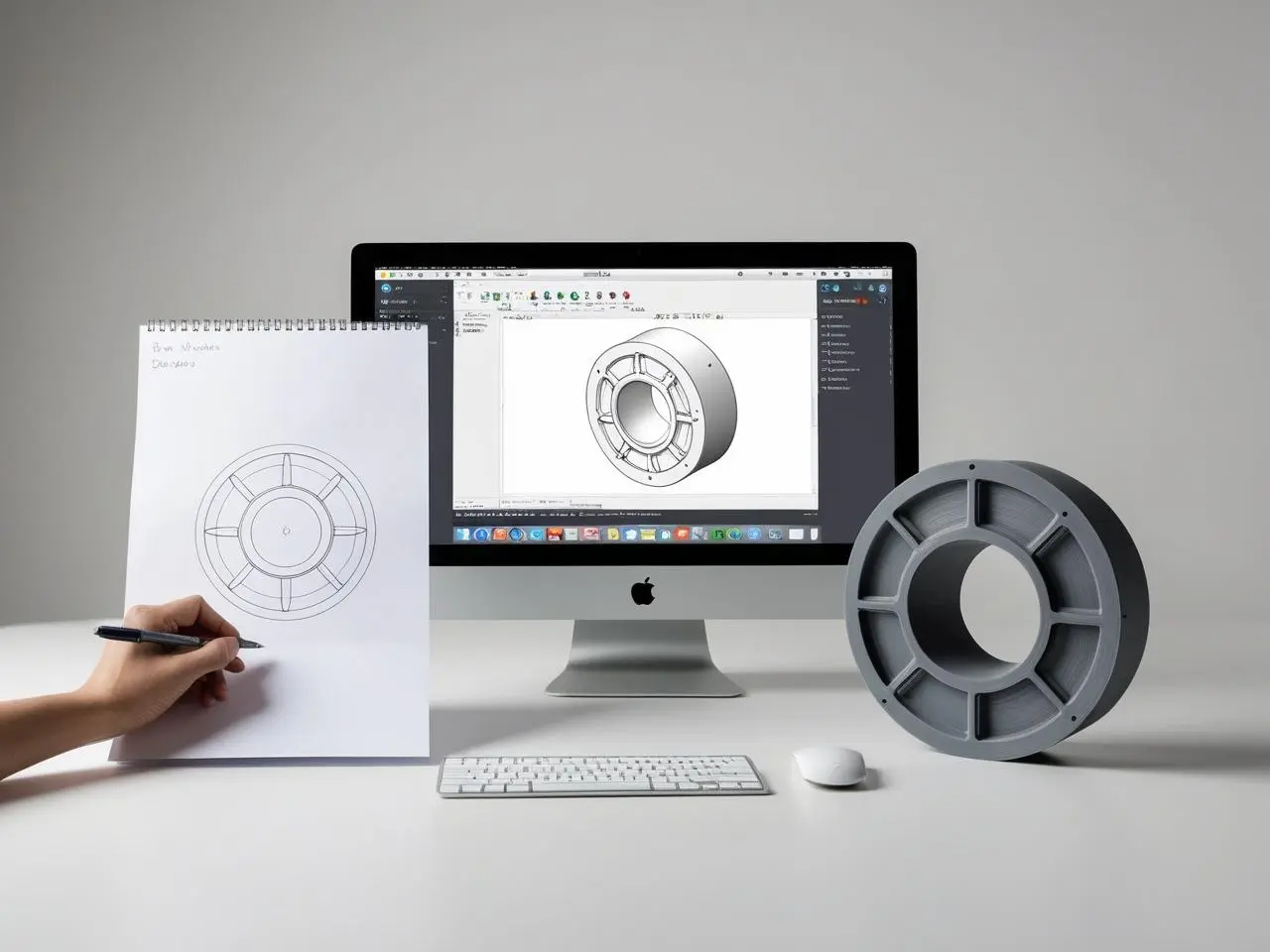

3D Drawing/Modeling Services

From idea to digital design – accurate, efficient, and production-ready

A good 3D model is the foundation of a successful final product. Whether it’s developing a new design, adjusting an existing model, or digitizing a physical form, professional 3D drawing and modeling ensures efficient and error-free production.

Using advanced software and technical expertise, each model is optimized for 3D printing, CNC machining, or other manufacturing techniques. Thanks to smart parametric designs, adjustments can be easily made, offering flexibility during the design process.

The Benefits of Professional 3D Modeling

Accurate, flexible, and cost-effective for any manufacturing method

Here are the key benefits that 3D drawing and modeling provide for your projects:

Accurate and Detailed Designs: Modern CAD software allows even the smallest details to be meticulously crafted, ensuring exact fits and smooth production.

Optimization for Production: Each model is analyzed and optimized for strength, material usage, and printability, ensuring it aligns perfectly with the chosen manufacturing method.

Efficient and Cost-Effective: With 3D modeling, designs can be tested and adjusted directly, eliminating the need for expensive molds or tooling.

Customizability and Flexibility: Parametric modeling allows for quick adjustments to models without having to redraw everything, ideal for prototyping and custom projects.

Compatibility with Various Manufacturing Methods: Designs are provided in different 3D file formats (such as STL, STEP, OBJ, IGES), making them suitable for various production methods, from 3D printing to CNC machining and laser cutting.

Why Choose RRU 3D Services?

Customization, speed, and quality for your unique designs

With our 3D drawing and modeling expertise, we can bring innovative designs to life quickly and accurately. Our team of experienced designers works closely with you to transform your ideas into practical, functional, and aesthetic solutions. Here are some reasons why clients choose our service:

Custom Solutions: Each project is unique, and we offer tailor-made designs that meet the specific requirements of your application, from concept to product.

Fast and Efficient: Thanks to advanced 3D design software, we can make quick adjustments and develop prototypes, saving you valuable time.

Creativity and Innovation: Whether it’s complex geometries or visually striking designs, we ensure that each design is not only technically feasible but also meets the desired aesthetics.

Reliability and Quality: Our designs are based on years of experience across various industries, allowing us to deliver reliable, durable, and high-quality solutions.

Collaboration and Communication: We believe in close collaboration with our clients, continuously receiving feedback to ensure the design perfectly aligns with your needs.

Workflow 3D Drawing/Modeling Services

From Concept to Production: Structured and Precise

When designing and modeling your product, we ensure a careful and structured process from the initial idea to the digital model ready for production.

Each step focuses on precision, efficiency, and collaboration to ensure that the final result meets your expectations.

In the initial phase of every project, time is taken for a detailed discussion of your needs and requirements. This forms the foundation for a successful design. We engage in conversation to understand:

- What is the goal of the design?

- Which technical requirements must be met?

- What are the aesthetic preferences and the intended use of the product?

- Are there specific materials or manufacturing techniques to be considered?

By carefully listening to your needs, we can establish a clear plan of action.

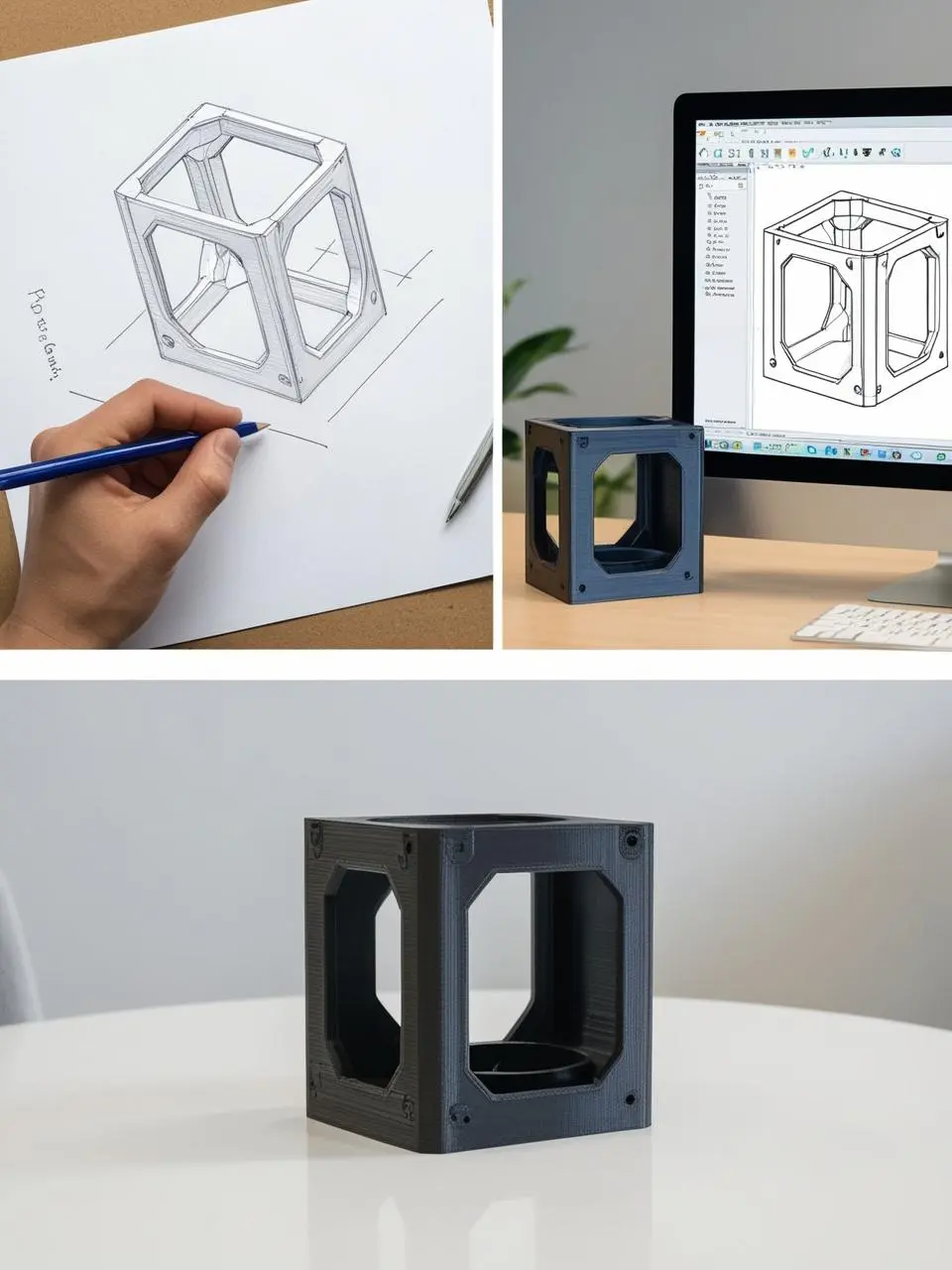

Once we fully understand your needs, we move on to the concept development phase. This can range from a quick sketch design to a more detailed visual concept. During this phase, we ensure:

- The development of multiple design concepts for greater choice.

- Feedback sessions to review if the design aligns with your vision and implement any improvements.

We present the first ideas and designs for approval and make adjustments if needed.

Once the concept is approved, the design is converted into a 3D digital model using advanced CAD software (Fusion360). This step includes:

- Building detailed geometries and the basic structure of the product.

- Optimizing the design for the chosen production method (e.g., 3D printing, CNC machining, or injection molding).

- The model is checked for accuracy, interference, and functionality.

If needed, the 3D model is optimized for parts under pressure, internal fits, or other specific production requirements.

After the first 3D model is created, you will have the opportunity to review the design. This is the moment to check if the model meets all your expectations. We offer two ways of feedback:

- Visualizations of the model in 3D format so you can thoroughly inspect the design.

- Physical prototypes if further testing and validation are needed. This can be done via 3D printing or other prototyping techniques.

If adjustments or improvements are required, we will modify the design and deliver a new version for approval. This step ensures there are no surprises during production.

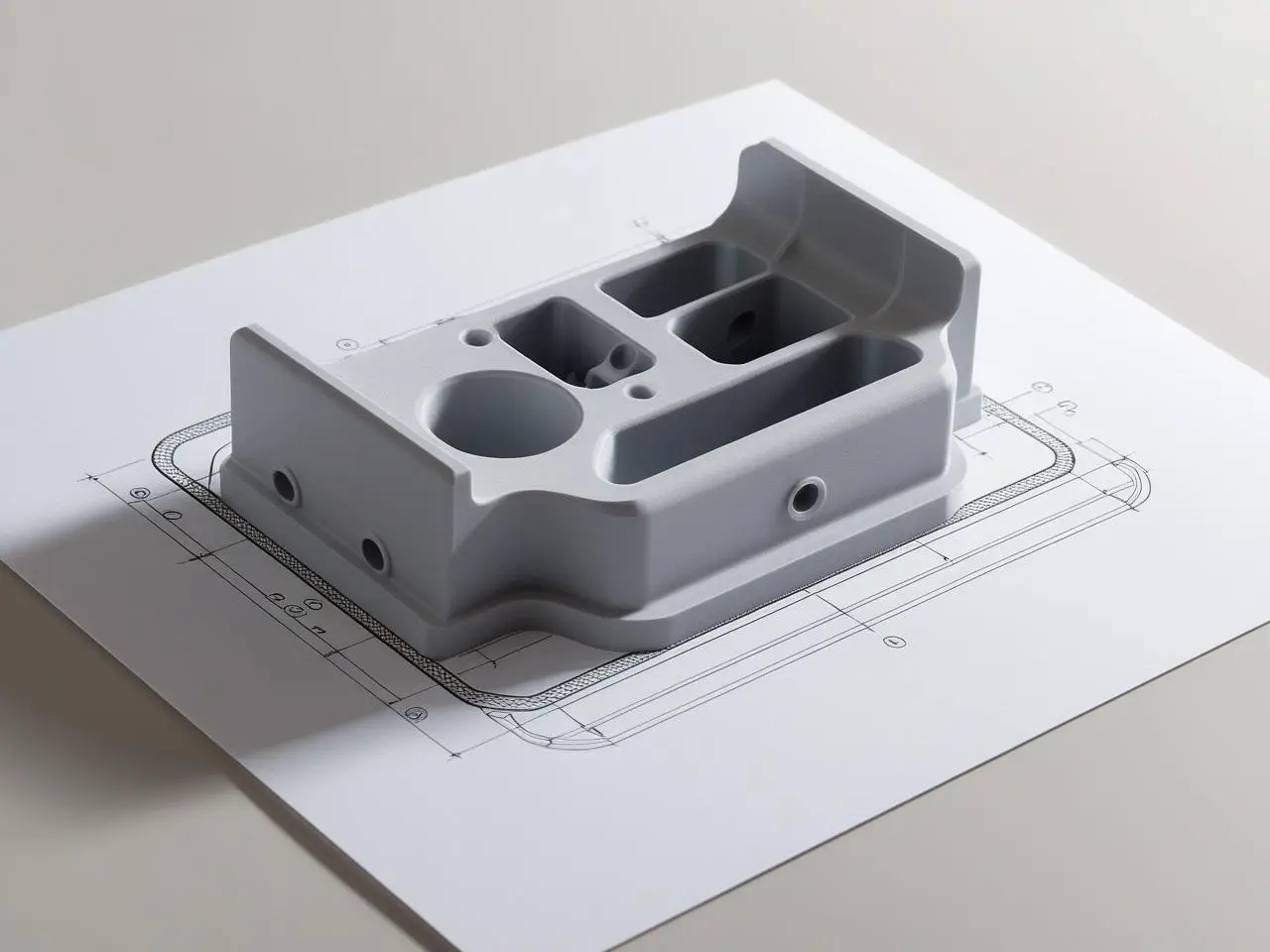

Once you are satisfied with the design, we proceed with finalizing the model. This includes:

- Optimizing the model for production (checking dimensions, tolerances, and material selection).

- Exporting the model in the appropriate format (STL, STEP, OBJ, IGES, etc.) to ensure compatibility with the chosen manufacturing technique.

- Providing a detailed report with technical specifications if required.

Once the digital model is approved, the design can be produced. This can range from 3D-printing prototypes to larger production batches using injection molding or CNC machining. We offer support for:

- Guiding the production of prototypes or final products.

- Selecting the appropriate production methods (such as 3D printing, CNC machining, or injection molding) based on the design type and intended application.

- Quality control and monitoring throughout the production process to ensure the final result meets expectations.

Request Form 3D Drawing and Modeling

Start Your 3D Design Today – Get in touch now and take the first step towards a perfect digital design.

Increase Your Project’s Efficiency – Discuss your design needs with our team and save time with innovative, accurate 3D drawing solutions.

From Sketch to 3D Model – Have a quick sketch or note? We turn it into a detailed 3D model.

ContactFrom Sketch to Reality? Get in Touch!

Bring your design to life with professional 3D modeling

Do you have a design that needs to be turned into a professional 3D model? Or would you like to digitize and optimize an existing part?

Contact us and discover how 3D modeling can take your project to the next level!