Prototyping Services

Speed, Precision, and Customization for Your Product Ideas

At RRU 3D Services, we understand that every product starts with an idea, but success lies in its execution.

With our prototyping services, we quickly transform your concept into a tangible product that can be tested, optimized, and perfected. We provide custom prototypes tailored to your specific requirements and expectations.

Benefits of 3D Prototyping

Faster, Cheaper, and More Flexible from Concept to Reality

Quick Turnaround: Thanks to 3D printing technology, prototypes can be produced in days instead of weeks. This accelerates product development and shortens time-to-market.

Cost-Effective: Instead of creating expensive molds or tools, we can print prototypes directly, significantly lowering initial costs.

Design Flexibility: With 3D printing, designs can easily be adjusted during the process. This provides enormous flexibility to make quick changes without incurring large costs.

Improved Functional Testing: Prototypes can undergo functional testing before mass production. This helps identify errors early and optimize the design for final production.

Simplified Communication: Visual prototypes allow ideas to be understood and communicated more quickly. This makes it easier to gather feedback from customers, team members, and investors.

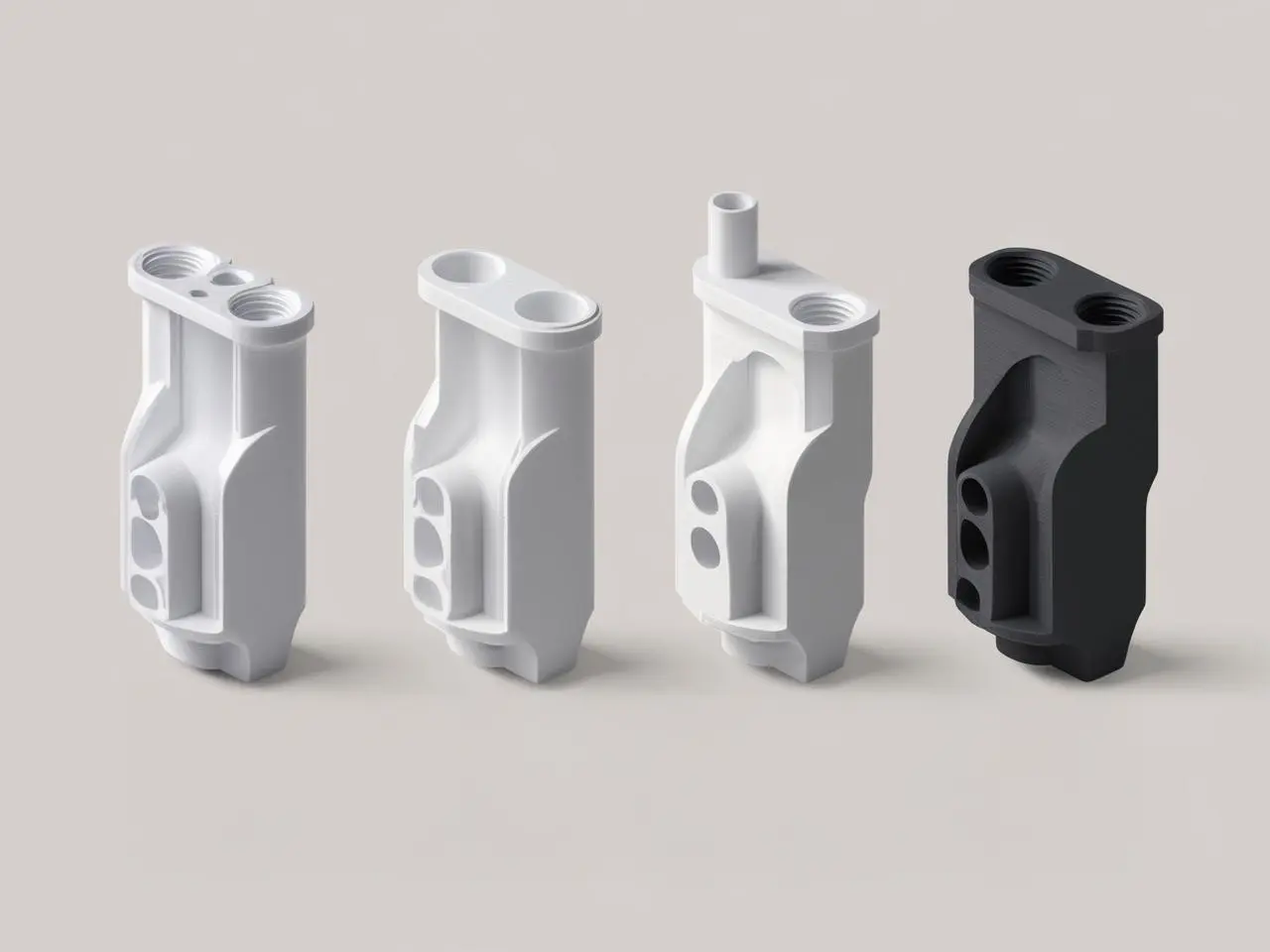

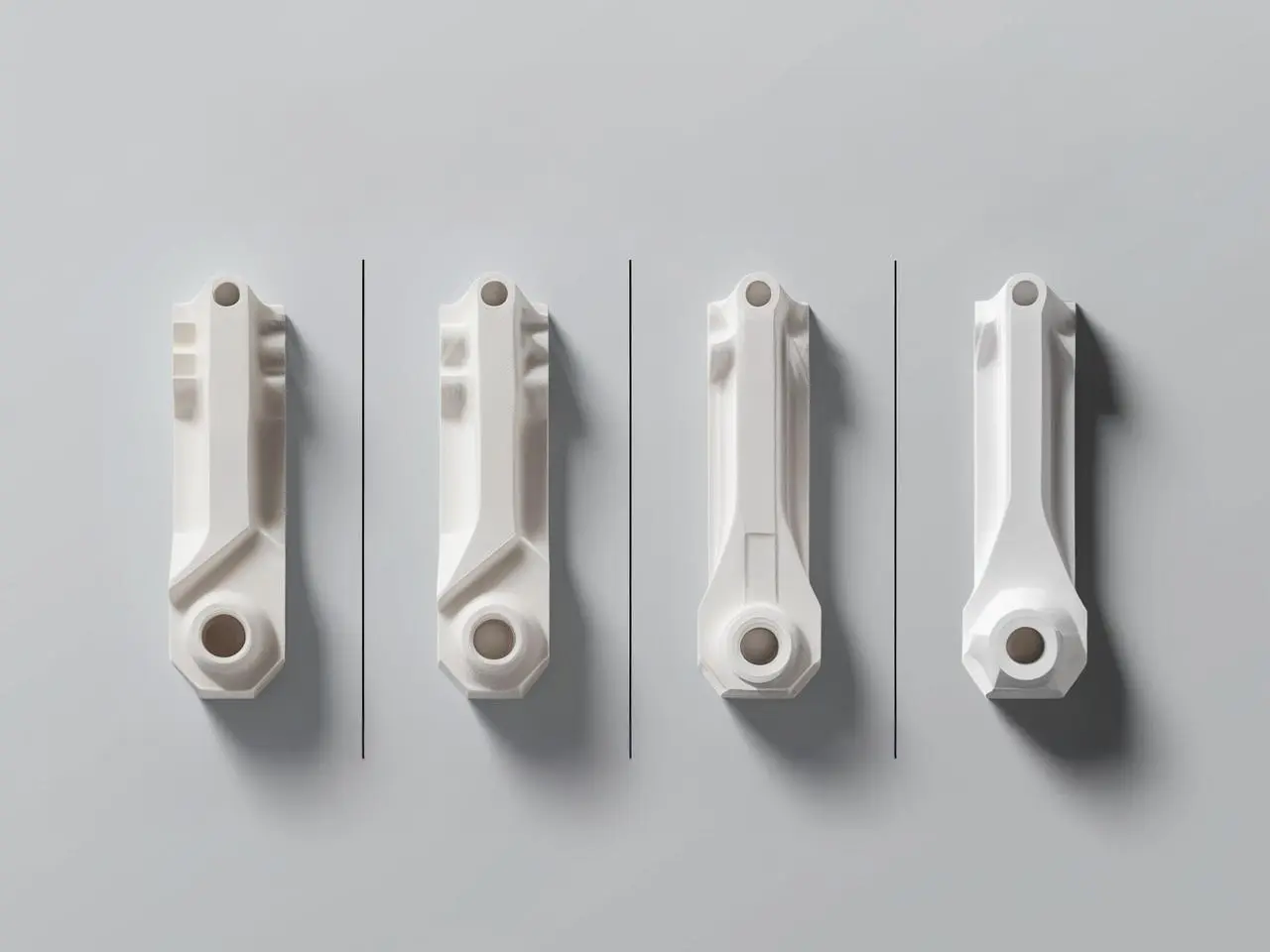

Applications of 3D Prototyping

From Idea to Tangible Model in Every Industry

Medical Equipment: Rapid prototyping enables the development, testing, and optimization of medical devices and tools for use in healthcare.

Consumer Products: From everyday items to design products, prototyping helps refine the form and functionality of a product before it goes into production.

Industrial Parts: Prototypes of industrial parts can be quickly tested for fit, functionality, and durability without the need to produce large quantities of a product.

Automotive Technology: For the automotive industry, prototypes of parts or accessories can be produced to test performance and integration into vehicles.

Model Making and Architecture: For architects or engineers, detailed scale models can be created of buildings or infrastructure projects to gain a better understanding of aesthetics and functionality.

Why Choose RRU 3D Services?

Innovative, Efficient, and Customer-Focused

Expertise and Experience: With years of experience in 3D printing and product development, we guide you from concept to final product, paying attention to both technical and aesthetic details.

Technological Innovation: We utilize the latest 3D printing technologies and materials to create prototypes that are not only visually appealing but also meet functional requirements.

Collaboration: We believe in working closely with our clients. The process is always interactive, with feedback collected and designs improved to create the perfect prototype.

Cost and Time Efficiency: Thanks to the benefits of 3D printing, we can deliver prototypes quickly and at a fraction of the cost of traditional manufacturing methods.

Our Process for 3D Prototyping Services

Fast, Accurate, and Customized

At RRU 3D Services, it's all about quickly and efficiently transforming your ideas into physical prototypes that function and meet your requirements. Whether it's an initial sketch or a fully designed product, we handle the entire process, from concept to test model, with precision and attention to detail.

Below, you'll find a detailed explanation of our 3D prototyping process:

We begin with an in-depth discussion to fully understand your product idea and requirements. This is a crucial step, as it helps determine the right approach for creating the prototype. During this phase, we will discuss:

- Your objectives for the prototype: What is the purpose of the prototype? Should it be functional, aesthetic, or used for testing?

- Technical requirements: What are the specific needs regarding dimensions, functionality, and performance?

- Timeline and budget: What are the desired deadlines and available budget for the project?

After this conversation, we will jointly decide on the direction the design should take and the specific requirements the prototype must meet.

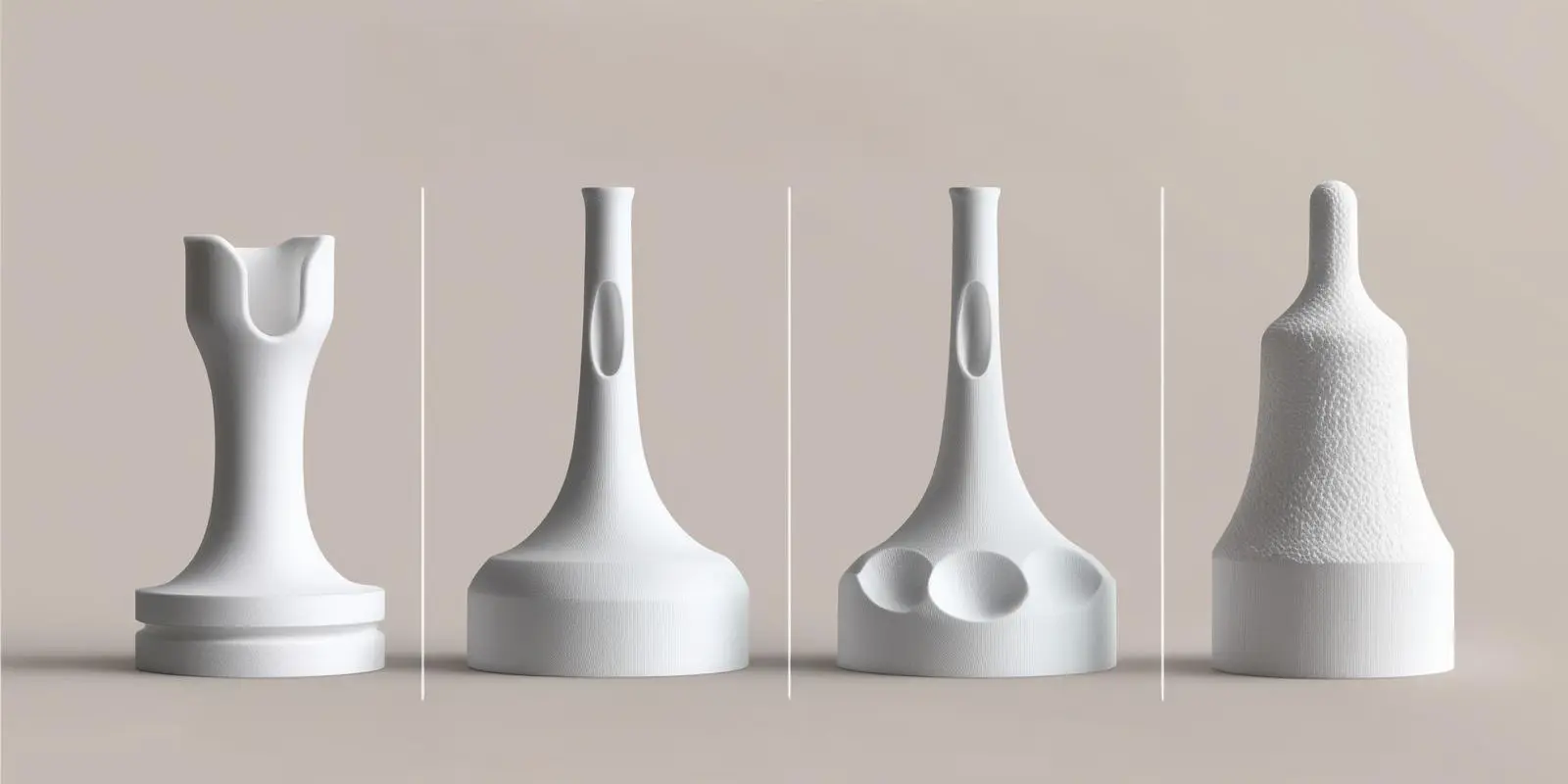

Based on your input, we begin designing the prototype. This typically follows these steps:

- 3D Modeling: Our designers create the digital 3D model of your prototype. We use advanced CAD software to make the design as accurate as possible. This ensures that both the technical and aesthetic aspects of the product are captured properly.

- Material Selection: Depending on the application and requirements of the prototype, we select the appropriate material. This could range from plastics, flexible materials, metals, or even high-quality composites, depending on the strength, durability, and functionality you need.

During this process, we ensure that you are kept informed and able to provide feedback, so we can adjust the design as necessary before moving forward with production.

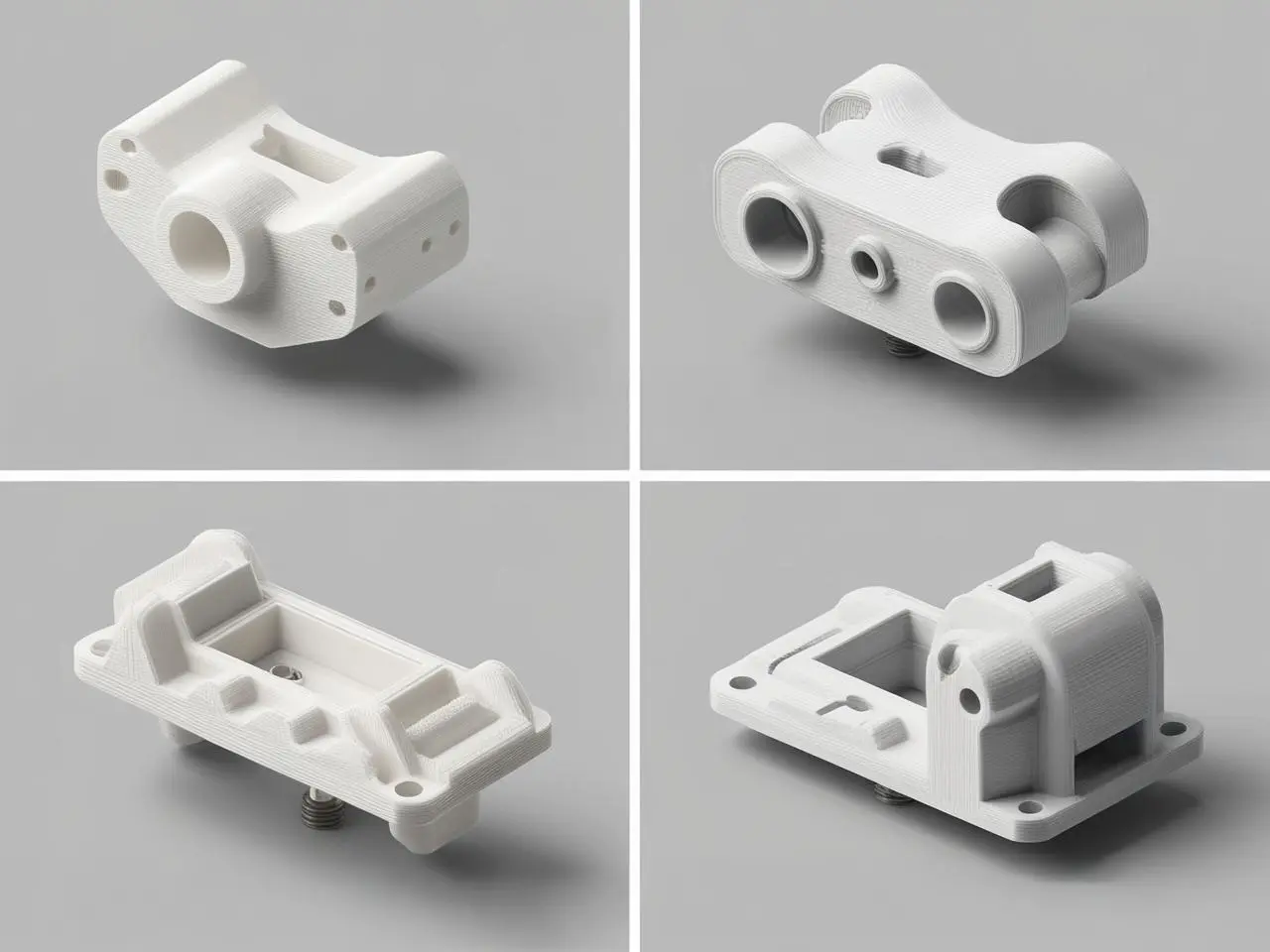

Once the design is approved, we move on to the production of the prototype. This is done through 3D printing and/or other advanced manufacturing techniques, depending on the project’s requirements.

- 3D Printing: We use the latest 3D printing technologies to produce the prototype quickly and accurately. This technology allows us to create complex geometries and detailed designs with a high level of precision.

- Other Manufacturing Techniques: If needed, we can also employ other manufacturing methods, such as CNC milling or casting, to create specific parts of the prototype.

Throughout the production process, we ensure strict quality control to ensure the prototype is accurately reproduced according to the design specifications.

After production, you will receive the prototype for evaluation. We schedule an evaluation meeting where we test the prototype together and collect feedback on:

- Functionality: Does the prototype perform as expected? Are there any technical aspects that need adjustment?

- Aesthetics: Does the appearance of the prototype meet your expectations?

- Performance: How does the prototype perform under different conditions (e.g., strength, flexibility, or durability tests)?

With this feedback, we can make improvements and implement adjustments to better align the prototype with your requirements. These may range from minor design changes to larger structural modifications.

Based on the feedback received, we make the necessary adjustments to the design. This may include:

- Redesigning parts to improve their fit or enhance functionality.

- New material choices if we discover that the selected material does not perform optimally for the prototype’s application.

- Improved manufacturing techniques for parts that do not meet the desired quality or precision.

Once the adjustments have been made, a new version of the prototype is produced, tested, and evaluated. In some cases, this process may require multiple iterations to perfect the final design.

After the completion of the prototype, you will receive the final product along with a detailed report on the design and production process. This report may include the following information:

- Technical specifications of the prototype.

- Materials and techniques used in the production process.

- Test results from the evaluation and feedback round.

At this stage, the prototype is ready for the next step in the product development process, whether it is mass production, test markets, or further improvements.

Request Form for 3D Prototyping Services

From Concept to Prototype: Discover how we bring your design to life.

Fast and Personalized Advice: Discuss your idea directly with our experts.

Request a Free Quote: Receive a quick, tailored price estimate.

ContactBring Your Ideas to Life

Contact us for a no-obligation discussion about your prototype!

Are you interested in a prototype that perfectly matches your ideas? Or would you like to learn more about our approach and capabilities? Feel free to contact RRU 3D Services. We’d be happy to discuss your project in a no-obligation conversation and work together on the best approach for your prototype.

At RRU 3D Services, we are ready to turn your ideas into a practical and functional prototype, so you can move forward with confidence in your development process.